Our Location

Building C Tengxiang district Aojiang Wenzhou Zhejiang China 325401

size: 54″X108″

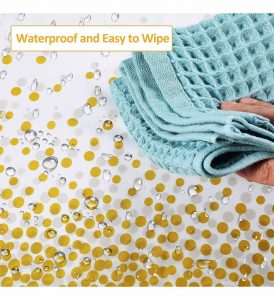

Printing method:rotogravure

Packing:1 pcs in opp bag with head card

Delivery time:15 to 30 days base on order quantity

The production process of plastic table covers typically involves several main steps, including:

Raw material preparation: The raw materials for plastic table covers, such as polyethylene or PVC, are prepared in a pellet form.

Extrusion: The plastic pellets are fed into an extruder, where they are heated and mixed. The molten plastic is then pushed through a die to create a sheet of the desired thickness.

Calendering: The plastic sheet is then passed through rollers, or a calender, to smooth out any unevenness and give the sheet a consistent thickness.

Printing: The plastic sheet is then printed with designs and patterns using various printing techniques such as rotogravure, flexography, or digital printing.

Cutting: The printed plastic sheet is then cut into the desired size of table covers.

Hemming: The edges of the table covers are then finished by folding over and sewing or heat sealing.

Quality control: The finished table covers are inspected for any defects or inconsistencies in color or pattern.

Packaging: The table covers are then folded and packaged for shipping or for retail display.

As with the paper product, different variables need to be considered in the production process, such as tablecover size, thickness, materials, ink, and more. In a real-world production environment, safety and environmental concerns must also be taken into account, as well as compliance with relevant national standards.

Reviews

There are no reviews yet.